Double click image to zoom in

Click image to open expanded view

A-SUB DTF Fine-Medium DTF Powder Adhesive White 1.1lbs

Brand:A-SUB

2 reviews

- Price

- $15.99

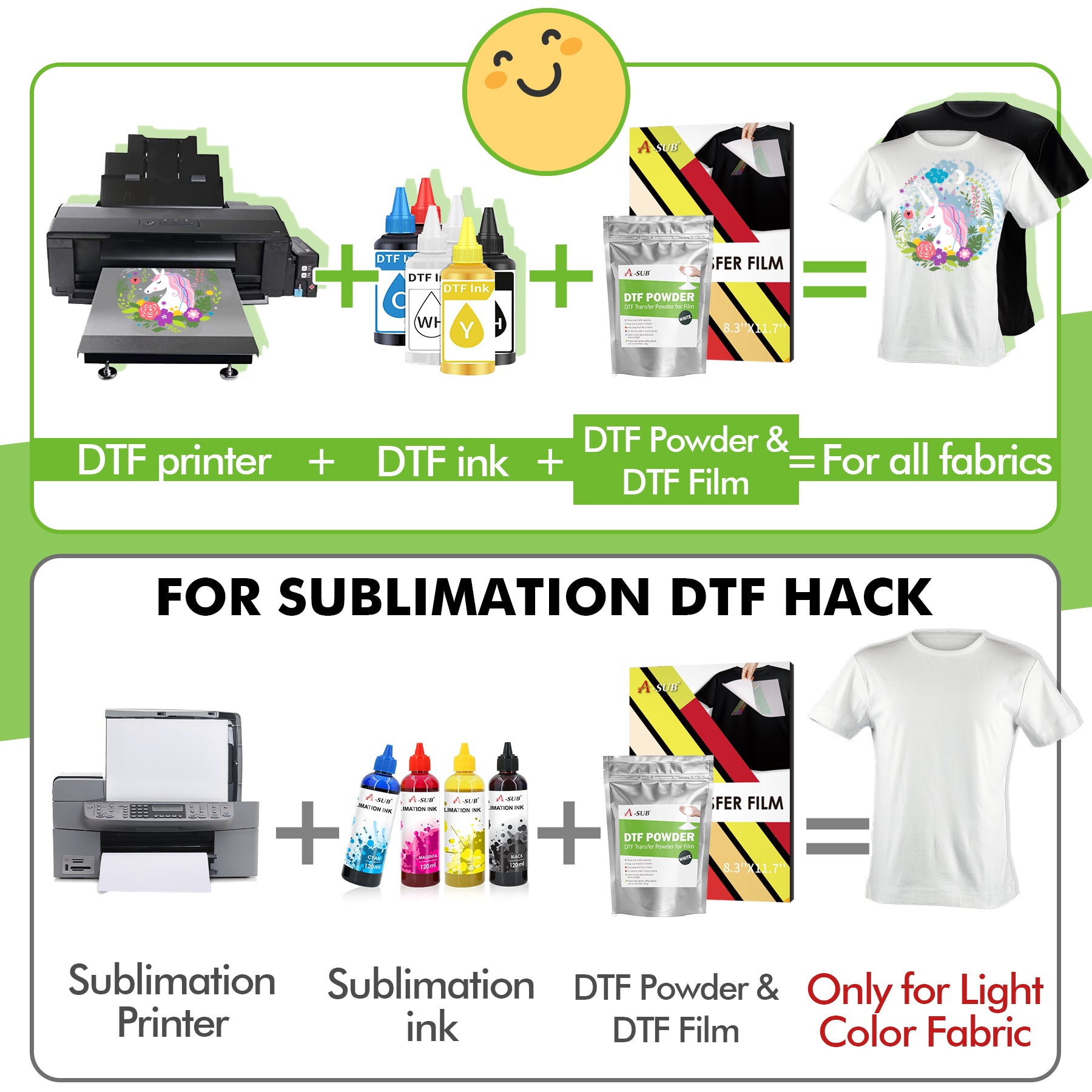

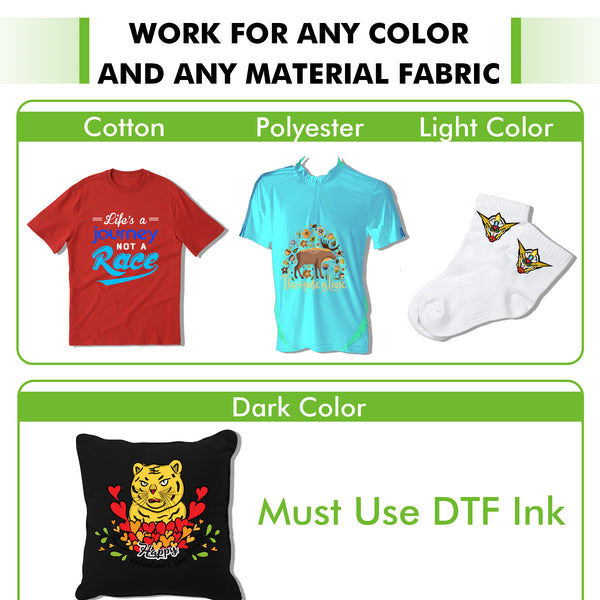

- 💪Super Adhesive & Super Glossy - A-SUB dtf powder for DTF ink transfer is soft and flexible to the touch, dtf transfer powder will stick to the ink, not to the film, no need to cut on the transferred image. Great for textile direct transfer printing, it transfers images with more vibrant and glossy colors and more vivid patterns than traditional heat transfers.

- 💪Wash & Flexibility - Resistant to water and dry cleaning & abrasion resistant. The excellent flexibility of sublimation powder for cotton keeps textiles from cracking and deforming, so you don't have to worry about peeling off the patterns printed on various garments.

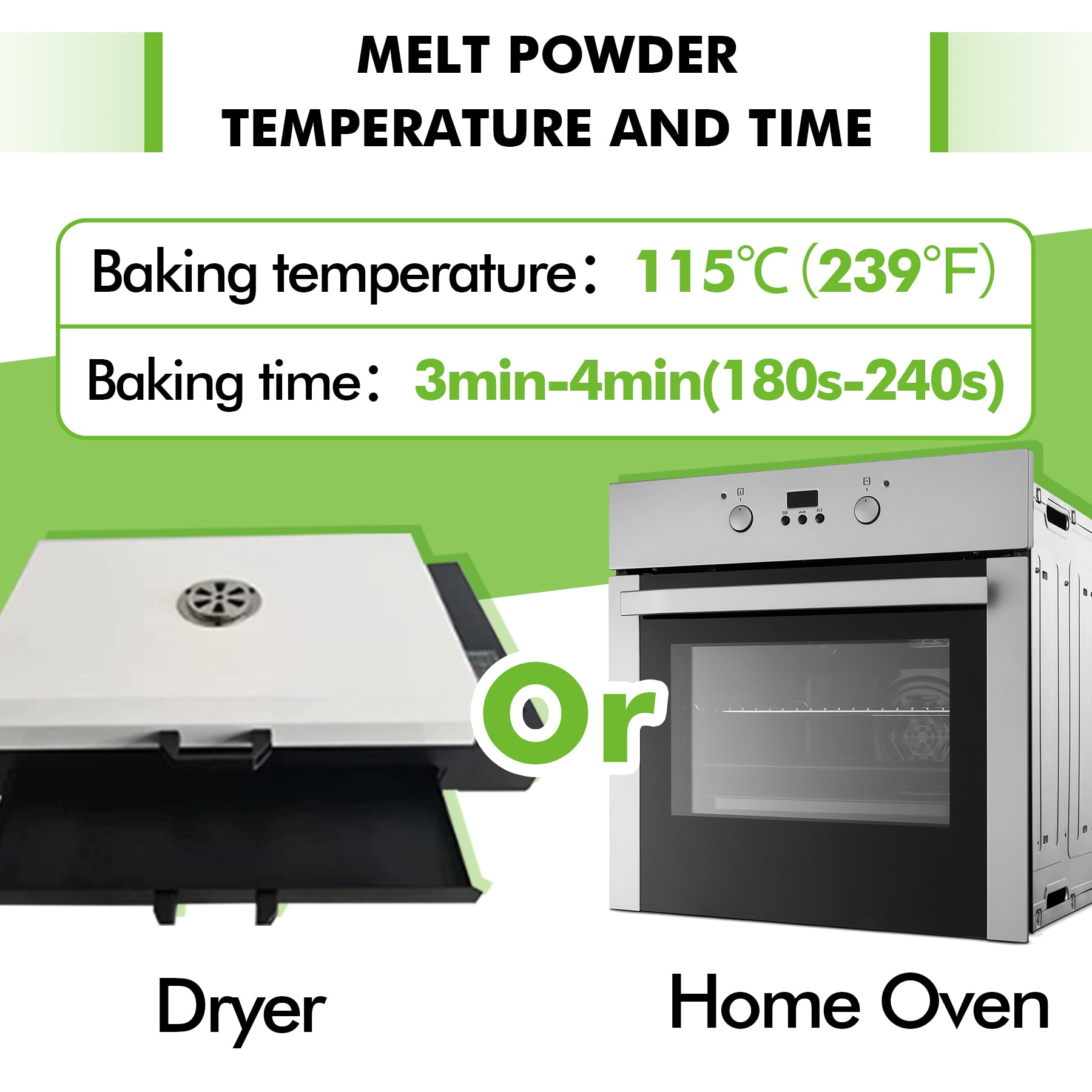

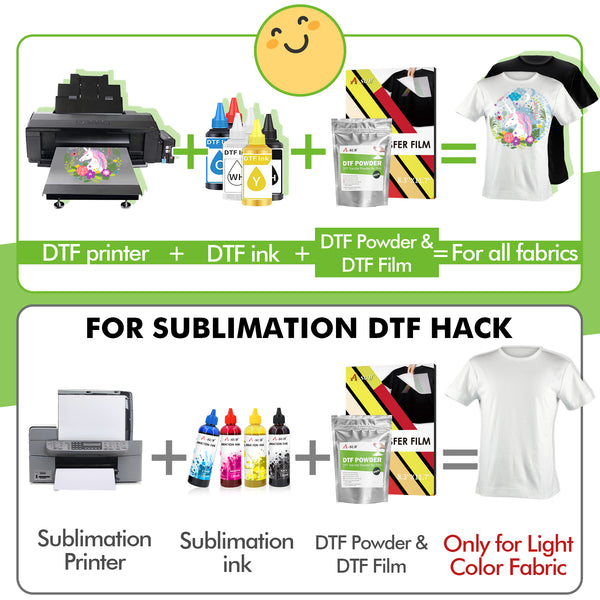

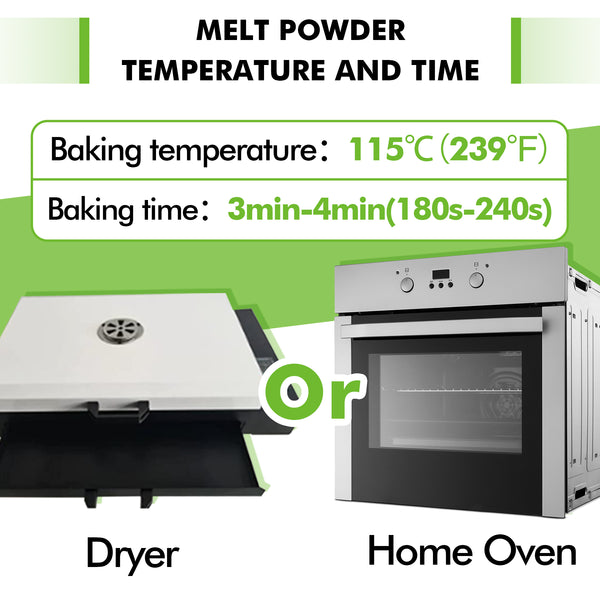

- 💪Printable On All Fabrics - A-SUB DTF powder can be transferred to garments of any material, especially suitable for cotton and polyester. Note: Dark colored garments can be transferred onto them as well. Attention! ! ! It is recommended to bake the black powder in the oven at 150°C for 6 minutes. Then its hot pressing temperature is 150°C and its hot pressing time is 10s, which is less likely to deform.

- 💪Easy Storage & Application - Our packaging is equipped with resealable zippers. Dtf powder requires no pretreatment and works with automatic shakers and hand applicators. Note: To use A-SUB DTF transfer adhesive, you will need a DTF printer and DTF film (not included in the package).

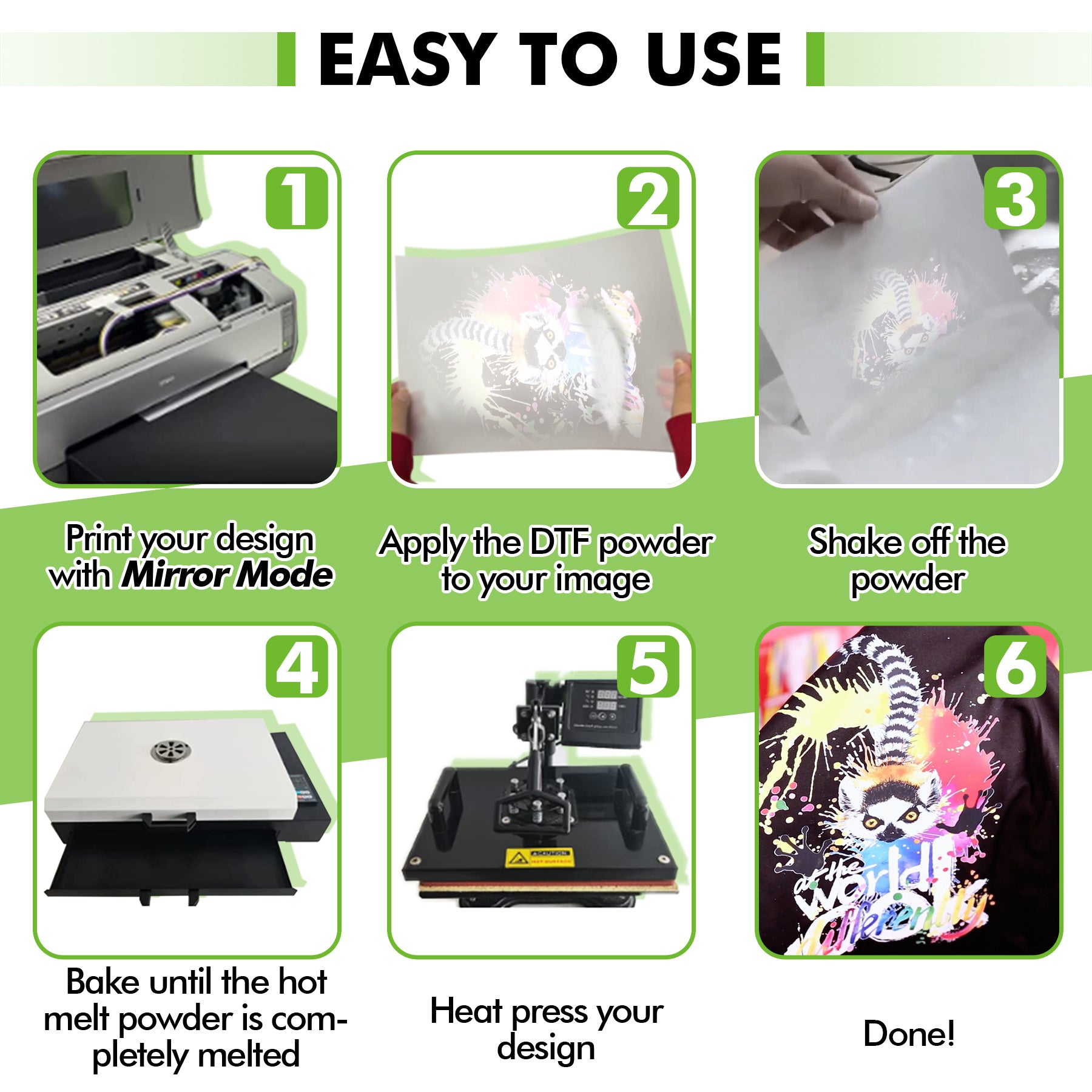

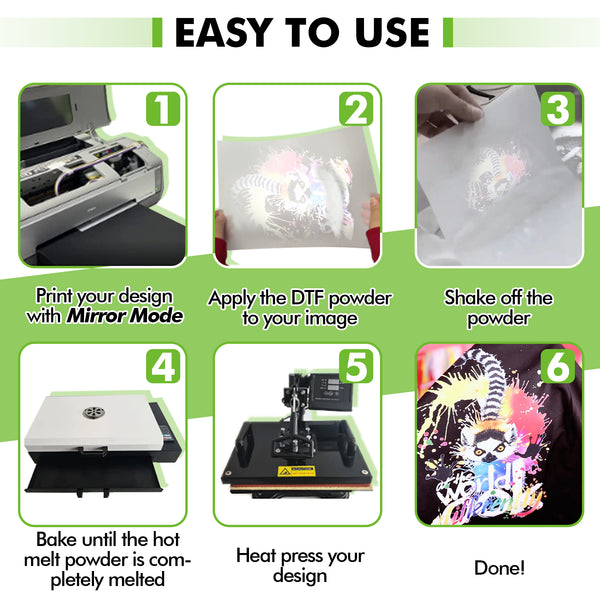

- 💪How To Use - Step 1: Use DTF printer to print your design on PET film (You need to prepare your own printer and film.) Step 2: Let the hot dtf powder for sublimation stick to the print, then shake off the excess powder; Step 3: Put the film into the oven and bake until the hot melt powder melts;

B

Beverly Nice!

S

Susan Bryant (Franklin, US) Some day when I actually get this product I will give you an honest review!