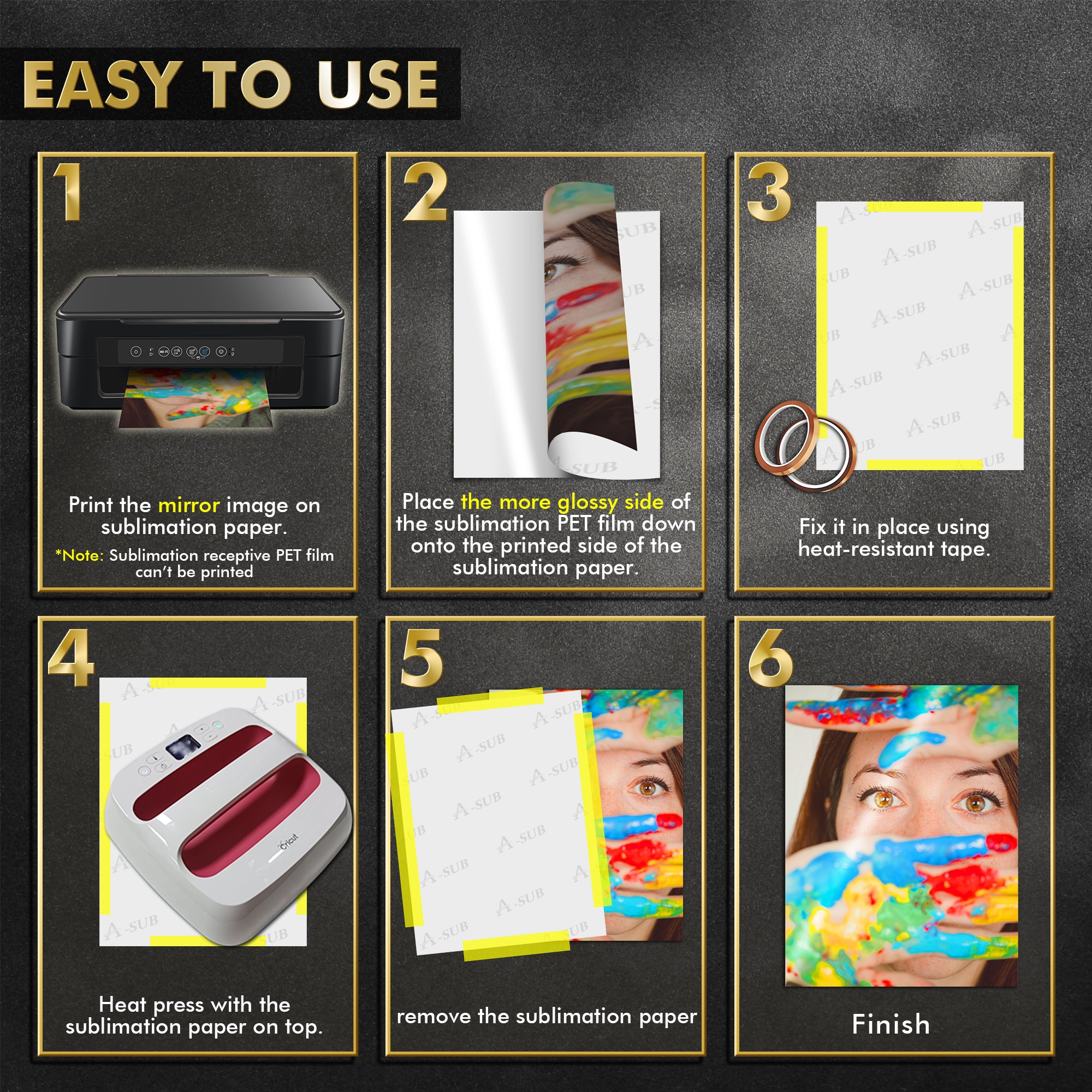

Create stunning large-format Cibachrome style displays with A-SUB Chrome Sublimation Receptive PET Film. A-SUB Receptive PET Film features a smooth, high gloss, bright white surface and is designed for use with prints produced on transfer paper. A-SUB Receptive PET Film can be sublimated using a flatbed or calendar heat press. it has vibrant colors and dense blacks, ideal for display in galleries and exhibitions.

Double click image to zoom in

Click image to open expanded view

A-SUB Chrome Sublimation Receptive PET Film (8.5 x 11", 5 Sheets)

Brand:A-SUB

No reviews

- Price

- $22.99

Key Features:

- Create Cibachrome Style Displays

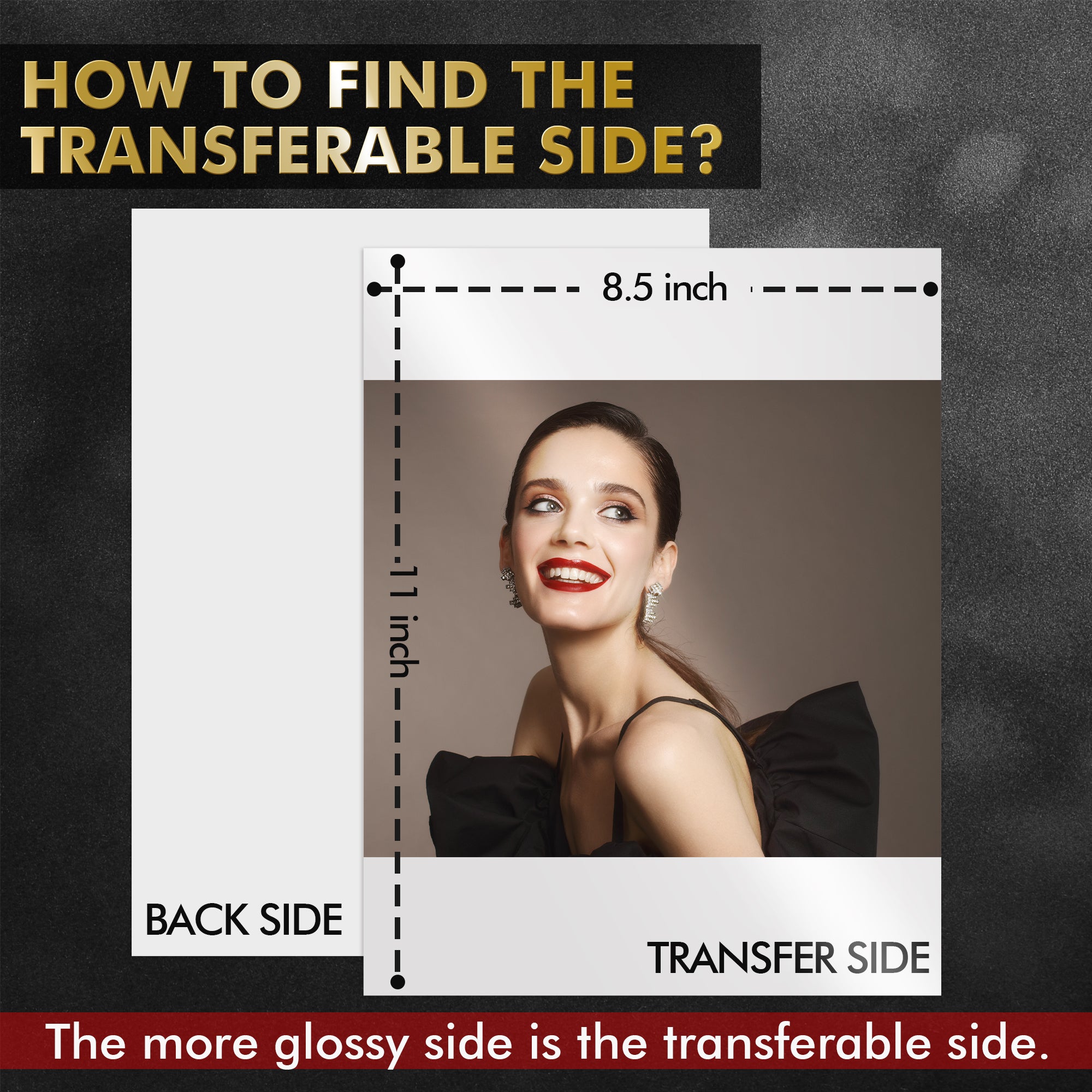

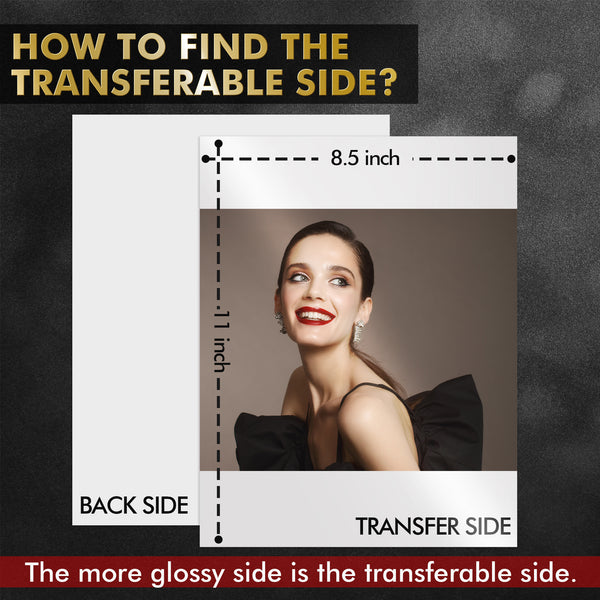

- Smooth High Gloss Bright White Surface

- Scratch and Solvent Resistant

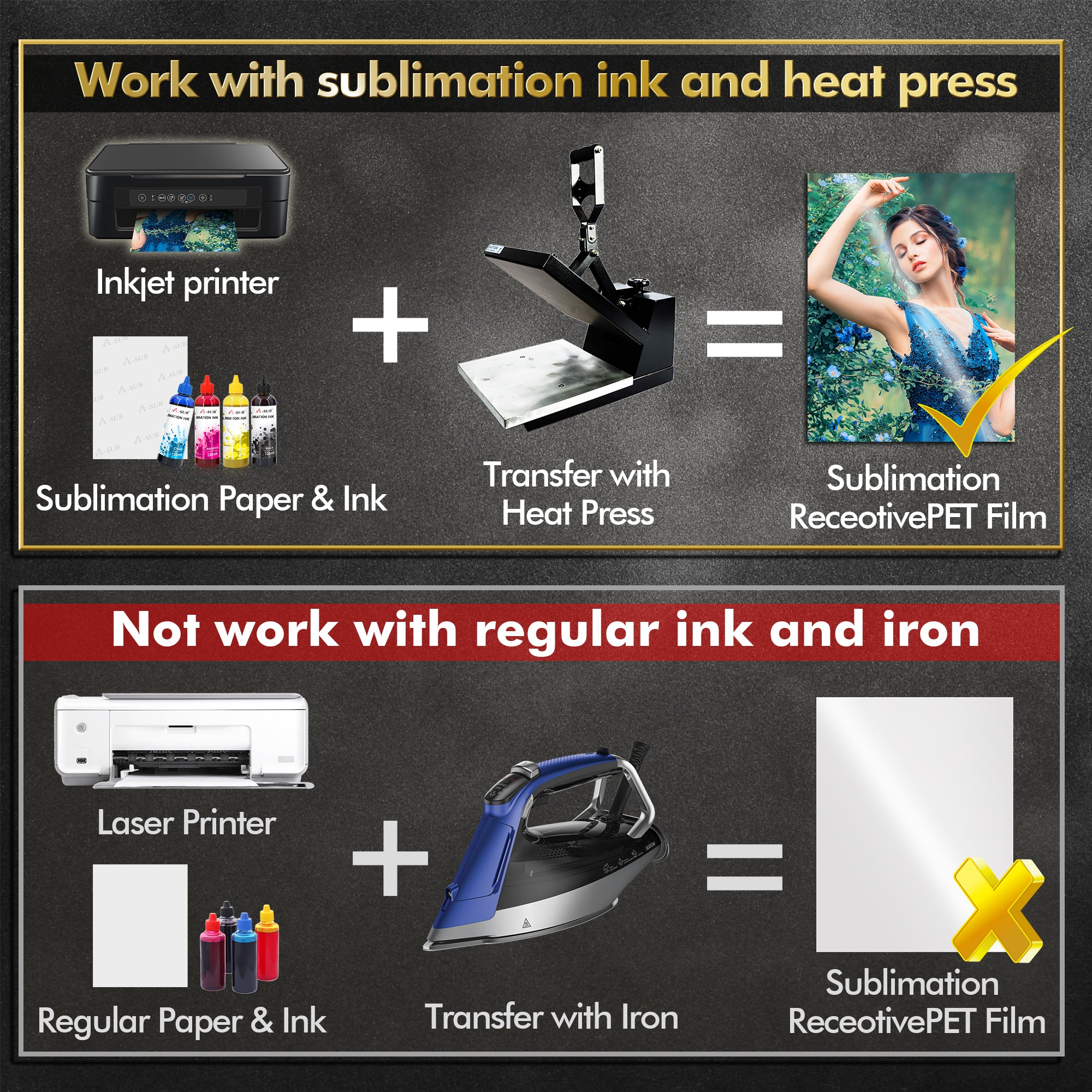

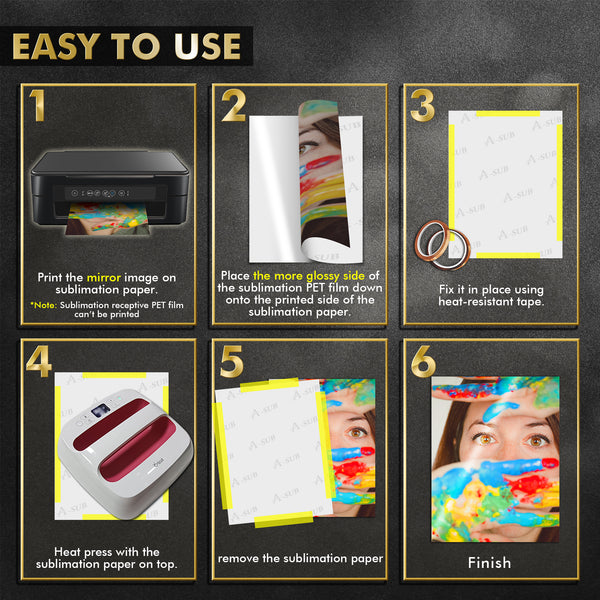

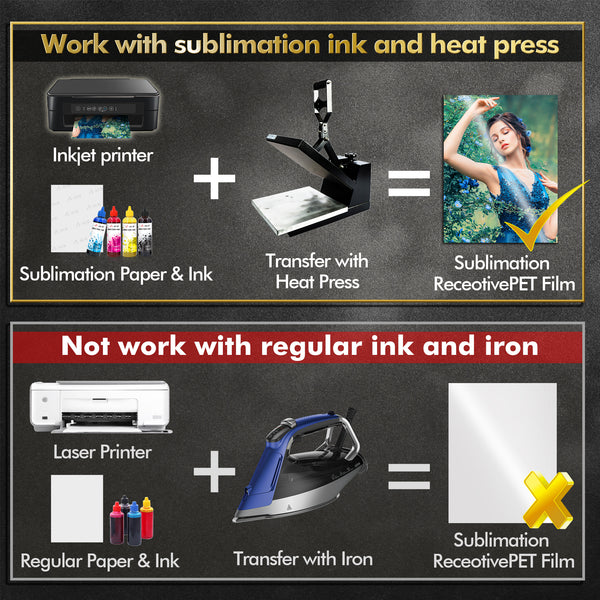

- For Transfer Paper Prints

Print / Heat Settings:

338°F temperature, for three minutes

Ink Compatibility:

Sublimation Ink.

Applications:

- Cibachrome style photographic prints

- Backlit displays

- Roller banners and flexible signage