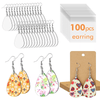

Earrings Teardrop Sublimation Blank Double-Sided 50 Pairs/100pcs

Brand:A-SUB X Koala

- Price

- $17.99

Versatile Double-Sided Design: Sublimation Earrings Blanks offer the unique advantage of being transferable on both sides. Whether you're a creative artist or a business owner, this feature allows you to showcase your designs or branding on both sides of the bookmark, doubling your promotional and creative opportunities.

High-Quality MDF Material: Crafted from durable Medium Density Fiberboard (MDF), these blank earrings are built to last. MDF is known for its smooth, flat surface, making it ideal for sublimation printing. Your designs will pop with vibrant colors and sharp detail, and the bookmarks will withstand everyday use.

Convenient Hook for Easy Customization: Each sublimation earring comes with a hook, making it effortless to assemble the earring. This feature adds a touch of convenience and time-saving.

What You Will Get: 100 pieces (50 Pairs) of blank earrings for sublimation, size: 1.57 in x 1 in x 0.12 in teardrop shape; all the unfinished blank koala sublimation earrings come with hook, kraft cardboard earring hanger, and clear bag. With 100 pieces per pack, you'll have an plenty supply of high-quality sublimation blanks to work with.

Endless Creative Possibilities: These sublimation earrings are a blank canvas for your creativity. Whether crafting personalized gifts, selling them in your store, sending them as gifts, or using them for promotional purposes, you can customize them with illustrations, quotes, logos, or photos to create unique and memorable keepsakes for yourself or your customers.